Get Instant Quality Info Now! Recirculating ball screw. A recirculating ball screw consists a screw , a nut and a series of balls.

The main difference between a recirculating ball screw and a power screw is that in former the sliding friction gets replaced by rolling friction. Since rolling friction is very less than sliding friction recirculating ball screw has very high efficiency of power transfer. The steel balls which rotates between screw and nut within ball return tube, at specific point. A ball screw achieves its smooth linear motion by recirculating steel balls along the screw groove within the nut.

The steel ball recirculation method differentiates the motion characteristics of the ball screw. Utilising the recirculating ball bearing nut technology as the base of the product, the Industrial class ball screws encompass screw diameters from 10mm up to 80mm as standard with Caccuracy. The ball screw drive is an assembly that converts rotary motion to linear motion (or vice versa).

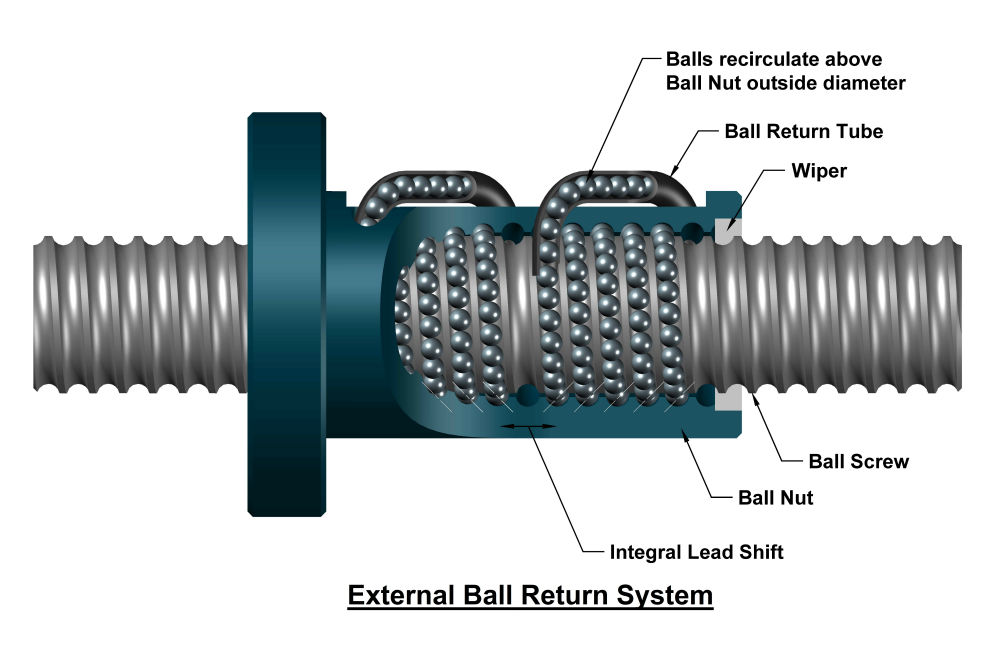

It consists of a ball screw and a ball nut packaged as an assembly with recirculating balls. The interface between the ball screw and the nut is made by balls which roll in matching ball forms. A few, including Chrysler, General Motors and Lada, still use this technology in certain models. Lack of sliding friction between the nut and screw lends itself to extended lifespan of the screw assembly (especially in no-backlash systems), reducing downtime for maintenance and parts replacement, while also decreasing demand for lubrication. Having a thorough understanding of how ball screw assemblies work is crucial when choosing a screw to meet your goals.

How do ball screws work? A ball screw assembly is comprised of four main components: the ball screw , the ball nut, a ball recirculation insert or tube, and the ball bearings. Each plays their own unique role in helping the assembly operate. As the screw or nut rotates, the balls are deflected by the deflector into the ball return system of the nut and they travel through the return system to the opposite end of the ball nut in a continuous path. The balls then exit from the ball return system into the ball screw and nut thread raceways continuously to recirculate in a closed circuit.

Ballscrews are often a first choice for linear-motion applications because the use of recirculating ball bearings provides high efficiency, load capacity, and positioning accuracy. Furthermore, ballscrews generally provide equal or better load capacity than leadscrews, and so are a better choice when load requirements exceed leadscrew capabilities. Return tube Example: 2. When the screw shaft is rotating, as shown in the illustration, a steel ball at point (A) travels 2. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional leadscrews, ballscrews tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. Photo showing two ball screws.

Inset images are close-up photos of the ball assembly of the top screw. The peculiar shape of the mixing nozzle directs the lubricant only to the parts in contact, avoiding lubricant dispersion and reducing the consumption. RECIRCULATING BALL SCREW. In order to purchase you must be.

A wide variety of recirculating ball screws options are available to you, such as rolled thread. Cerca qui la traduzione tedesco-italiano di recirculating Ball screw nel dizionario PONS! Trainer lessicale, tabelle di coniugazione verbi, funzione di pronuncia gratis.

Many translated example sentences containing recirculating ball screw – Italian-English dictionary and search engine for Italian translations. The name “ball screw” comes from the recirculating ball bearings within the screw used to reduce friction between the surfaces. Each ball screw assembly features matching helical grooves with its nut that eliminate the sliding friction found in other types of screws. Lead screws do not use these recirculating ball bearings. The recirculating - ball steering gear contains a worm gear.

The first part is a block of metal with a threaded hole in it. You can image the gear in two parts. This block has gear teeth cut into the outside of it, which engage a gear that moves the pitman arm shaft (see diagram above).

Nessun commento:

Posta un commento

Nota. Solo i membri di questo blog possono postare un commento.